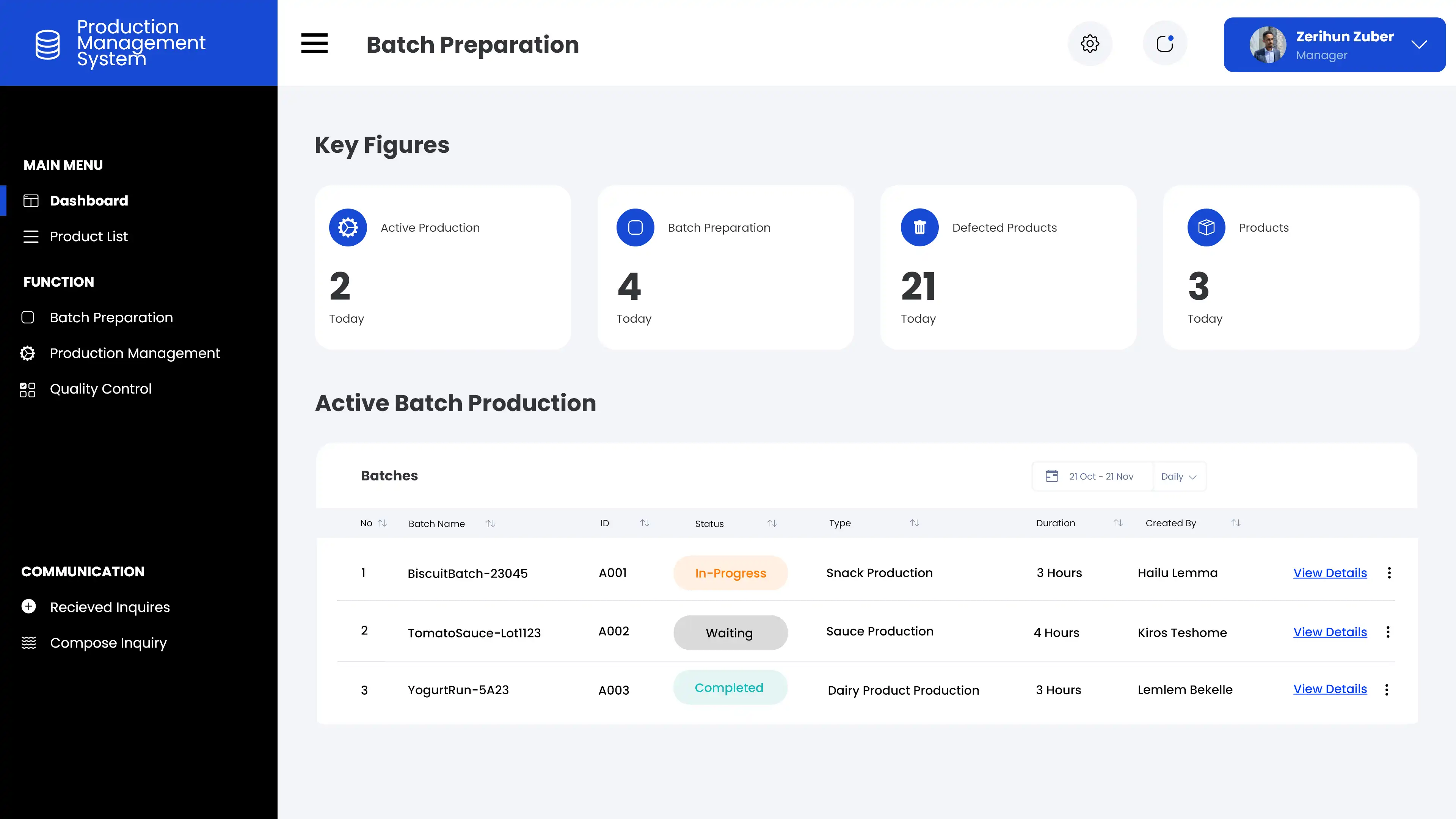

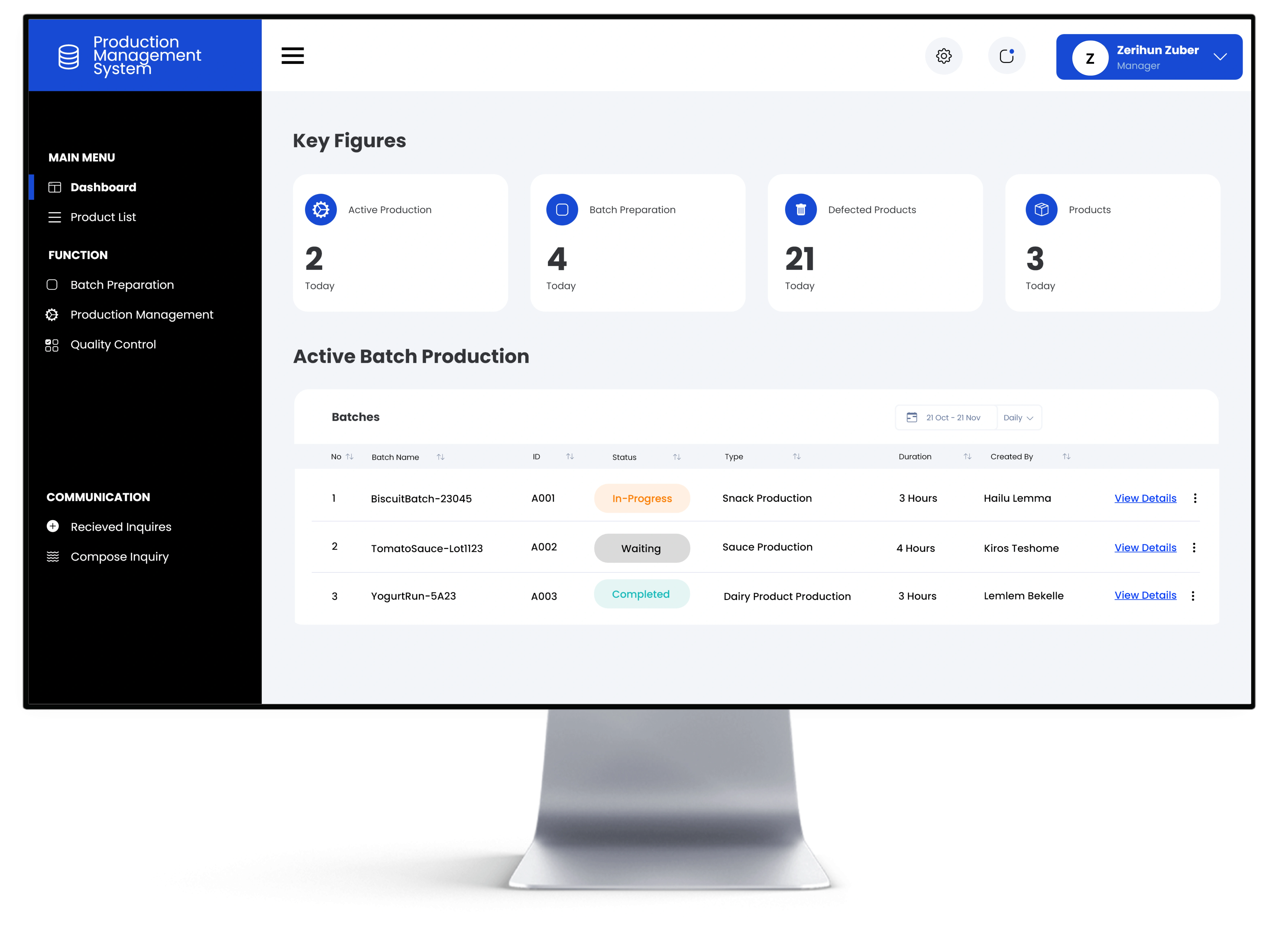

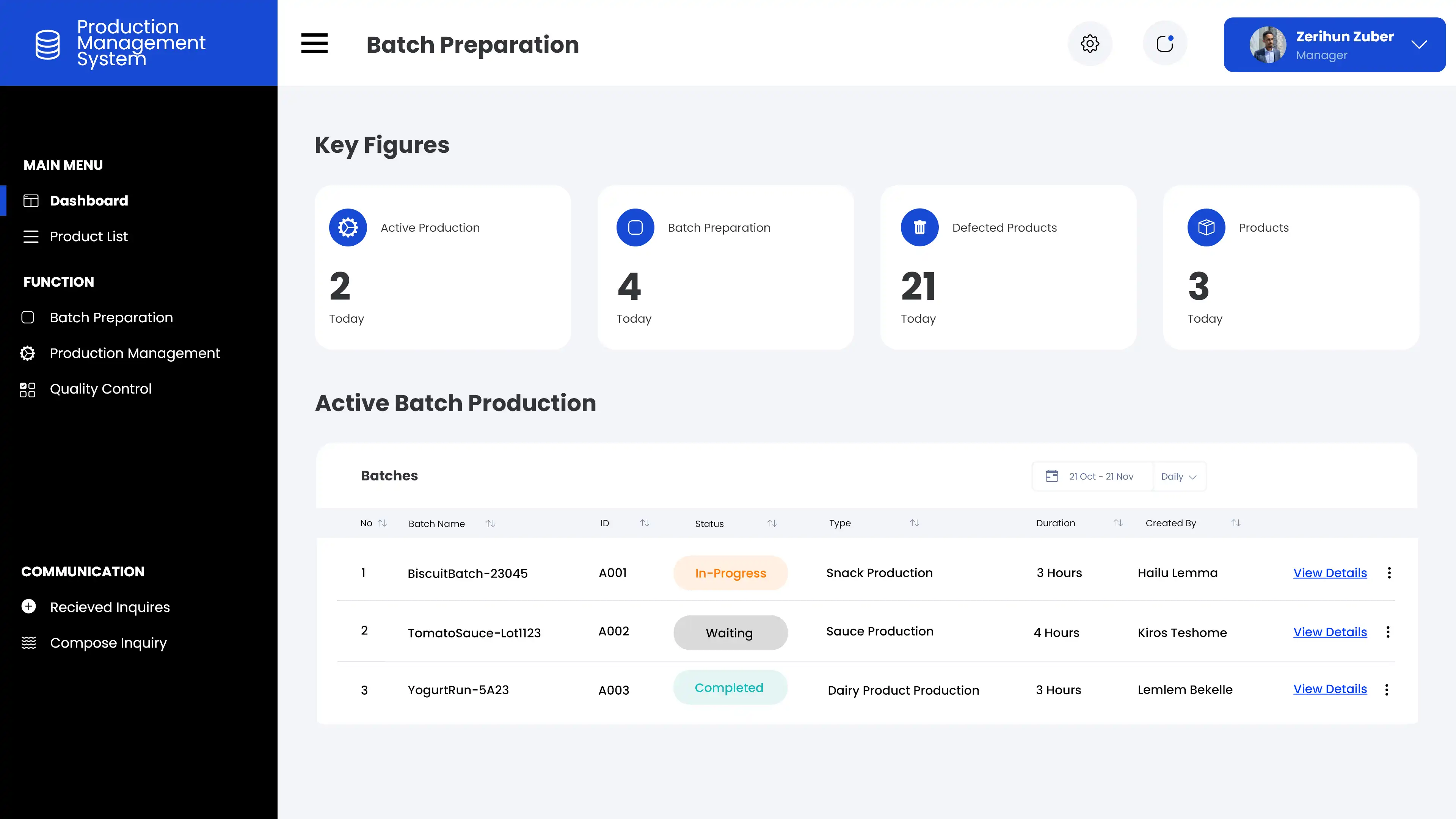

Dashboard

Monitor and manage your entire manufacturing process with real-time data, performance tracking, and operational insights.

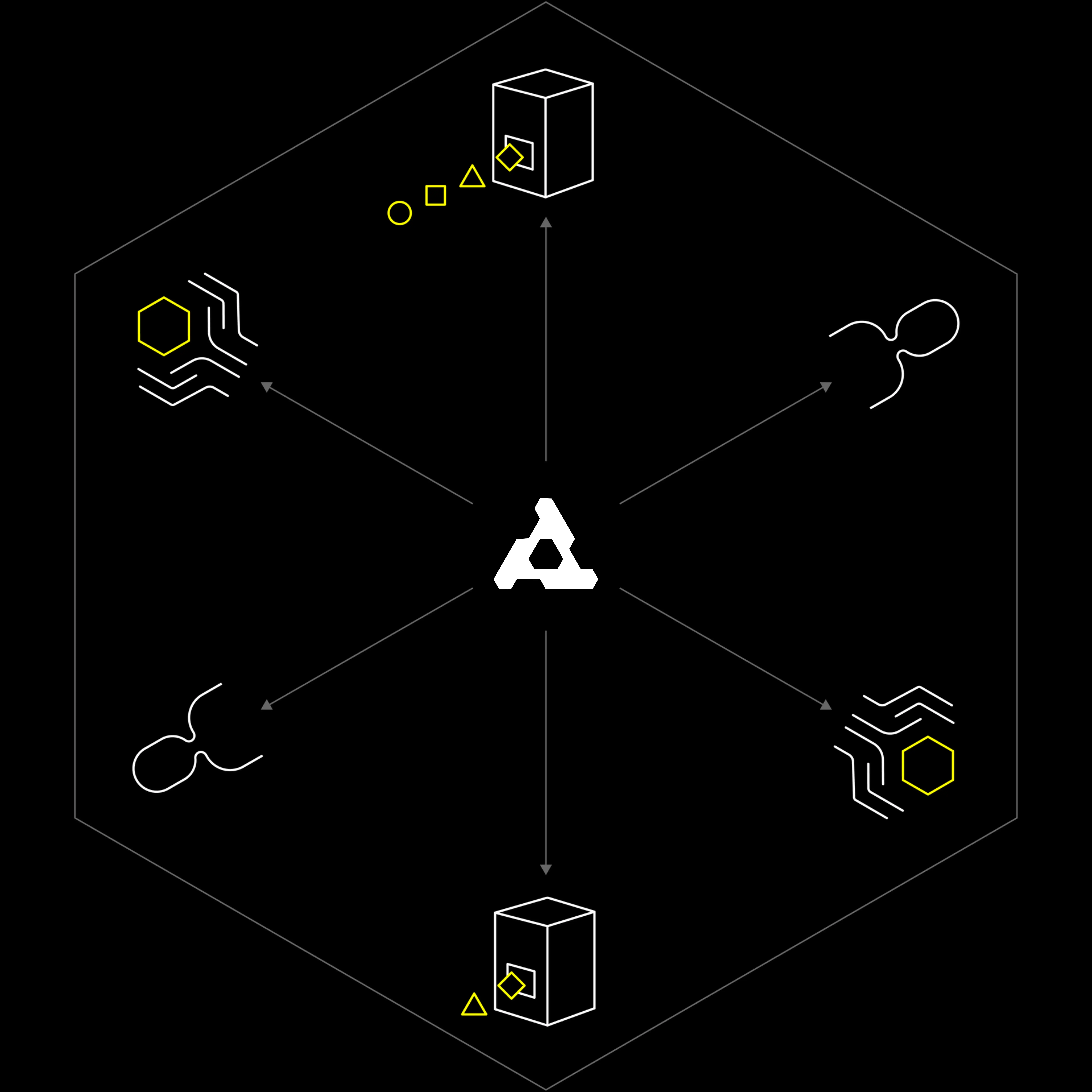

TRIDAL BUSINESS INFRASTRUCTURE

Streamline production and quality control for improved efficiency and growth.

Tridal Technologies’ production management system offers real-time monitoring, automated scheduling, and seamless integration with supply chain and inventory processes. With multi-facility support and powerful analytics, it enhances production efficiency and optimizes resource utilization.

Manage batch creation, track batch usage in production, and monitor waste to optimize efficiency and minimize losses.

Ensure all finished products meet quality standards through automated inspections and reporting.

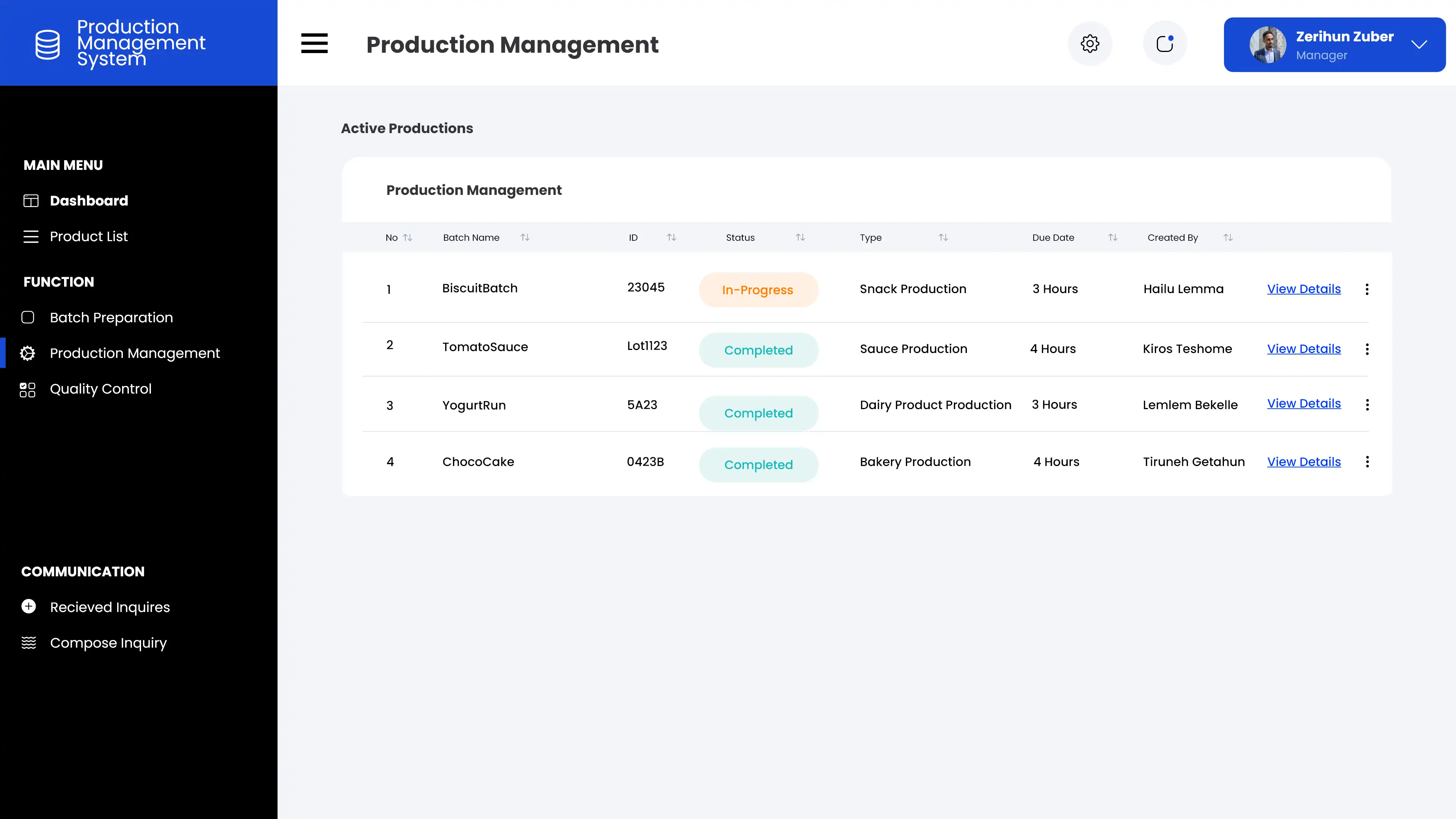

Track production progress, machine performance, and workflow updates instantly to minimize downtime.

Get notified when stock reaches a predefined threshold to ensure timely restocking.

Coordinate production across multiple plants or units with centralized control and resource allocation.

Ensure seamless tracking of raw materials, supply levels, and procurement to prevent shortages or overstocking.

Gain insights into production efficiency, waste reduction, and output trends with detailed performance reports.

Monitor and manage your entire manufacturing process with real-time data, performance tracking, and operational insights.

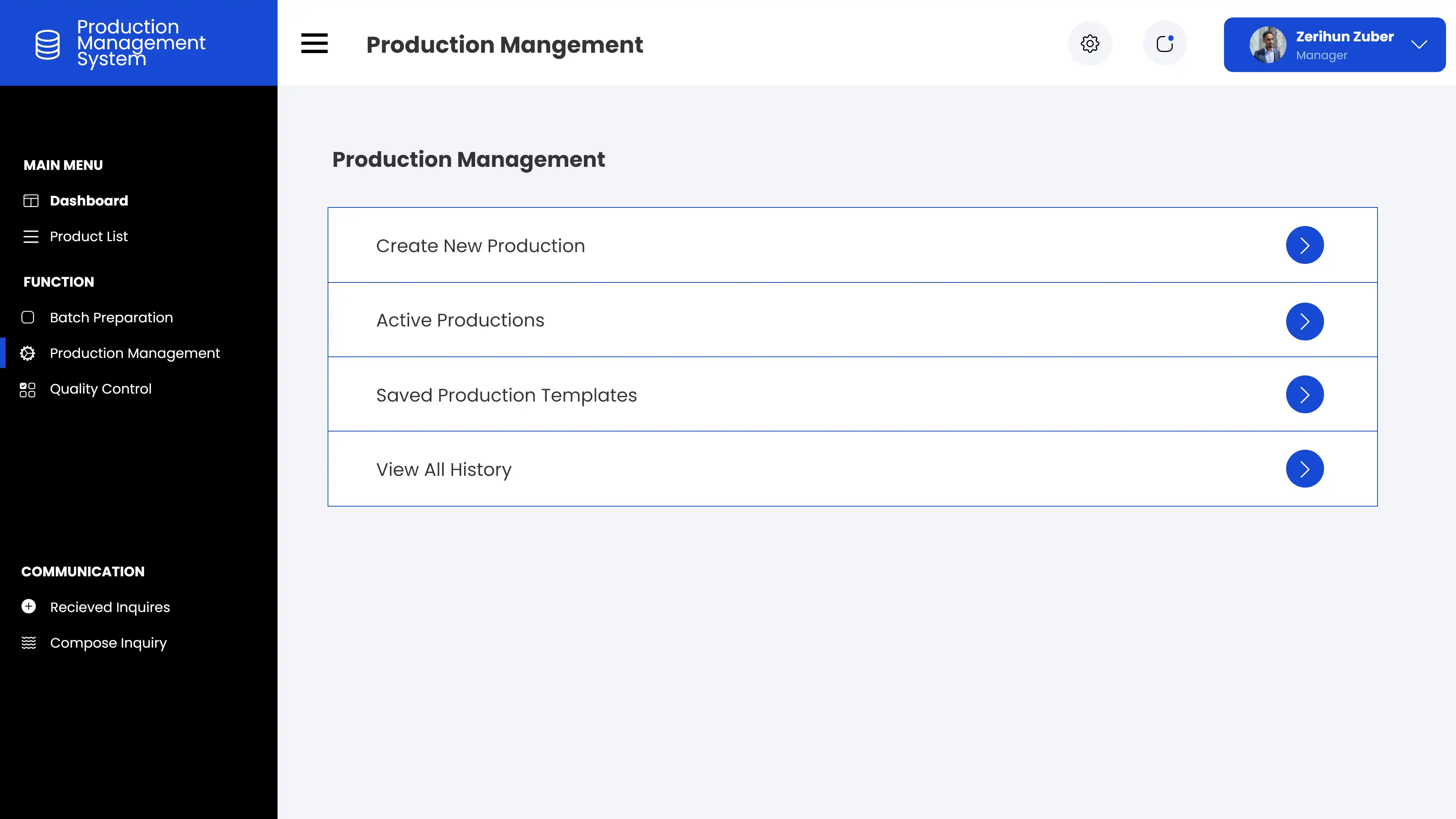

Streamline manufacturing operations by defining and optimizing production workflows for maximum efficiency.

View and manage active and completed production orders, ensuring smooth operation and task coordination.

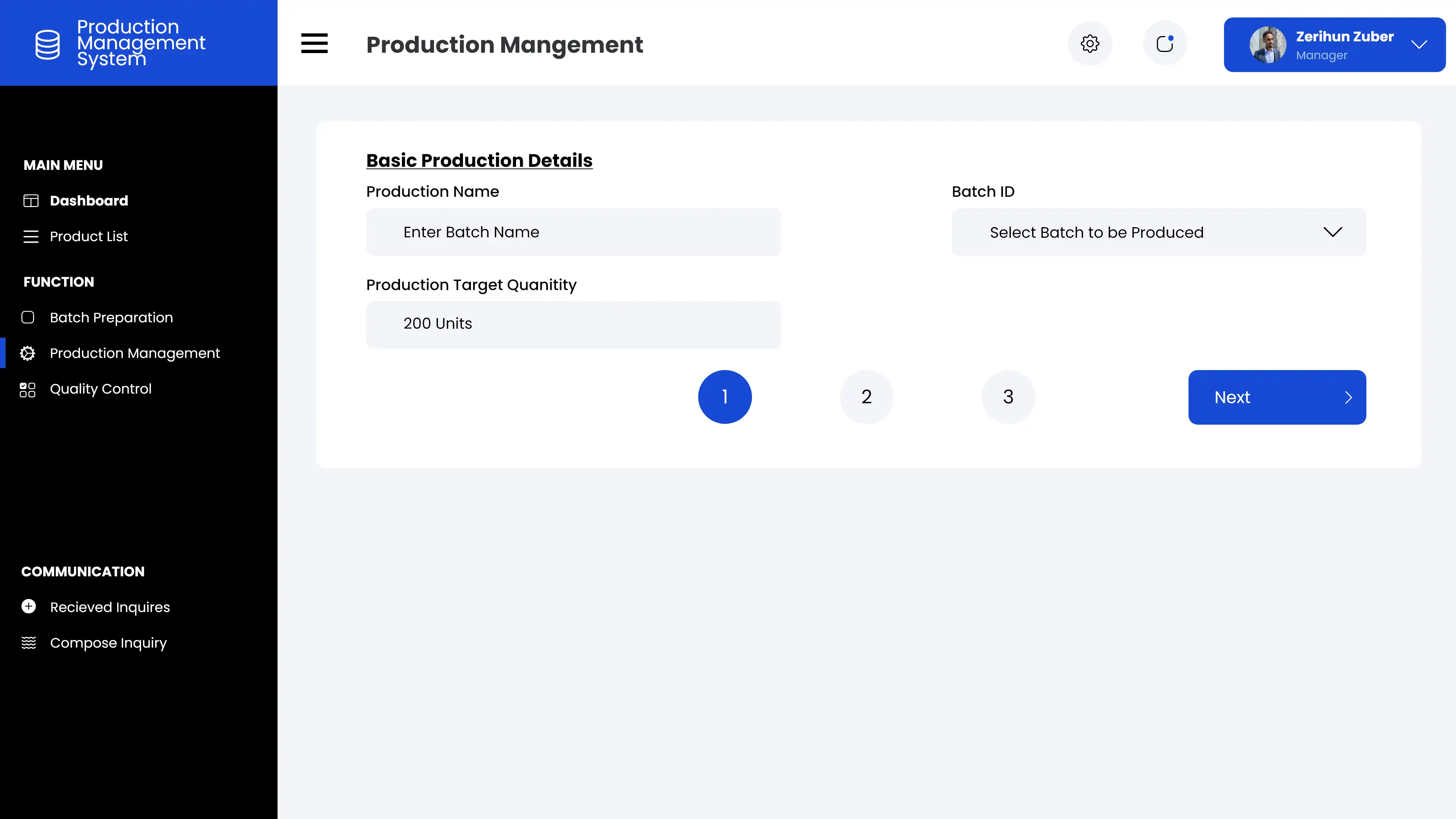

Define product specifications, raw material requirements, and production goals for each manufacturing task.

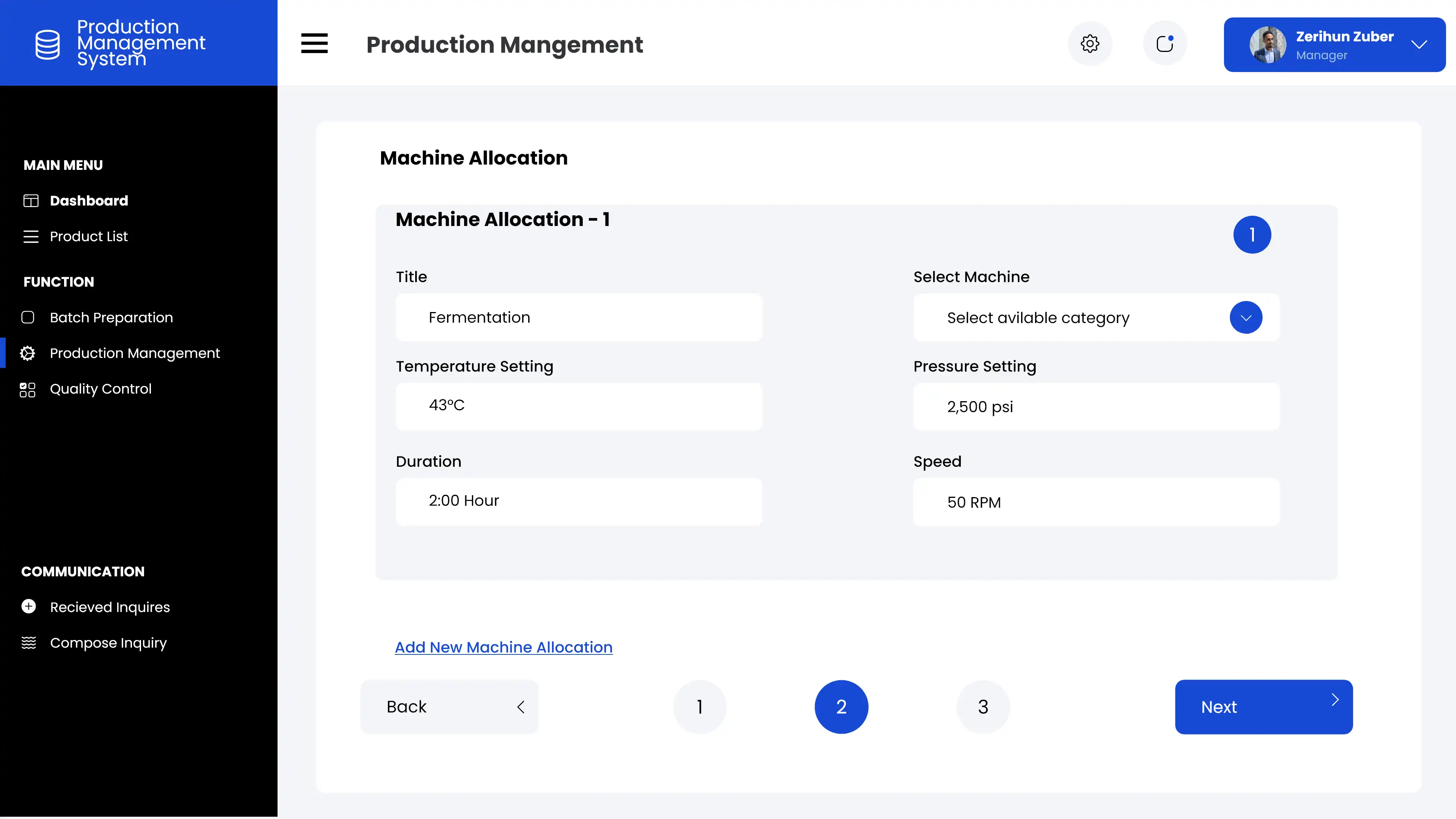

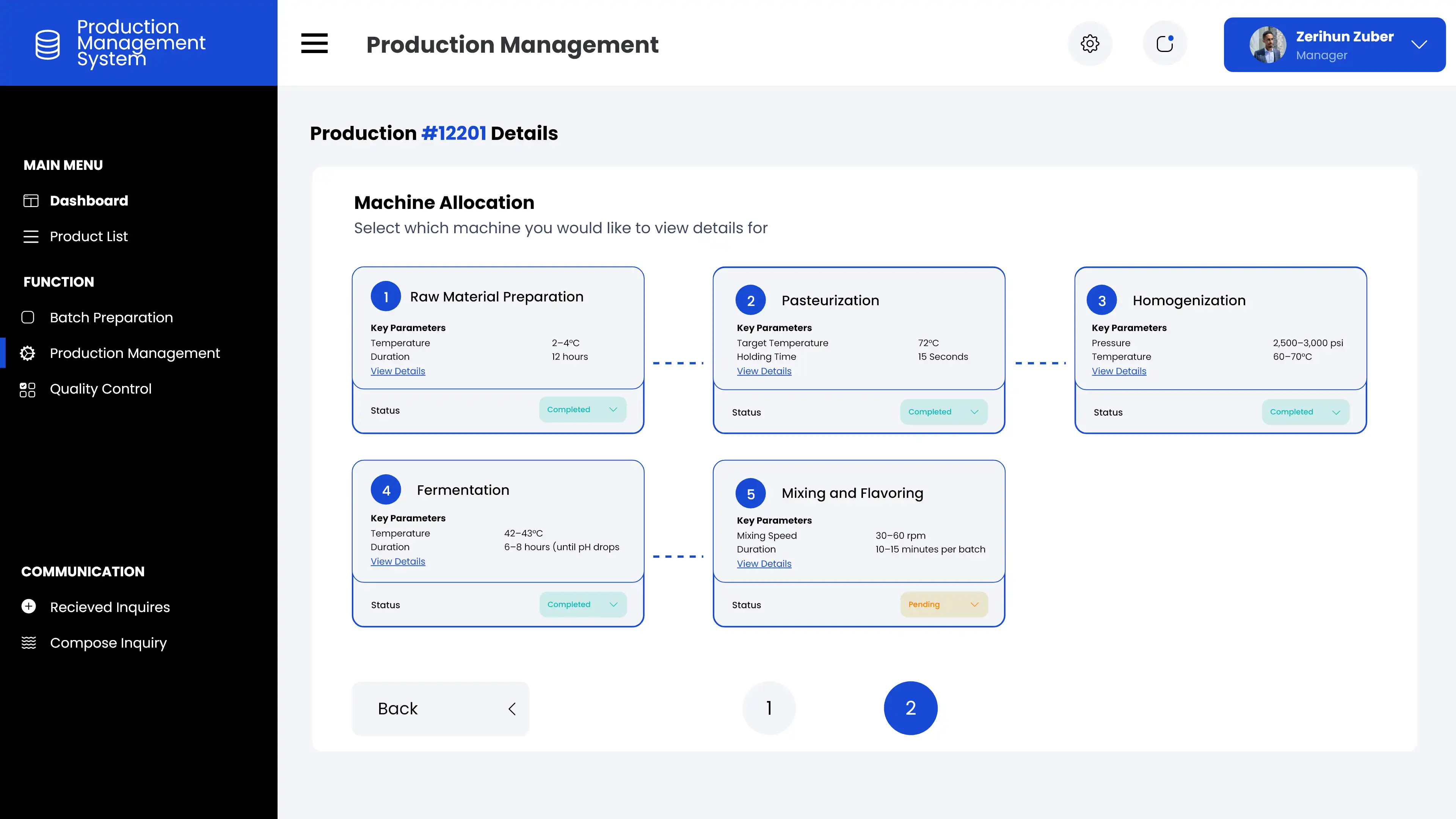

Assign machinery and resources efficiently to ensure optimal production capacity and minimize downtime.

Plan and coordinate production timelines to optimize throughput and meet delivery deadlines.

View all production processes by machine with real-time status tracking, ensuring clear oversight and smarter allocation decisions.

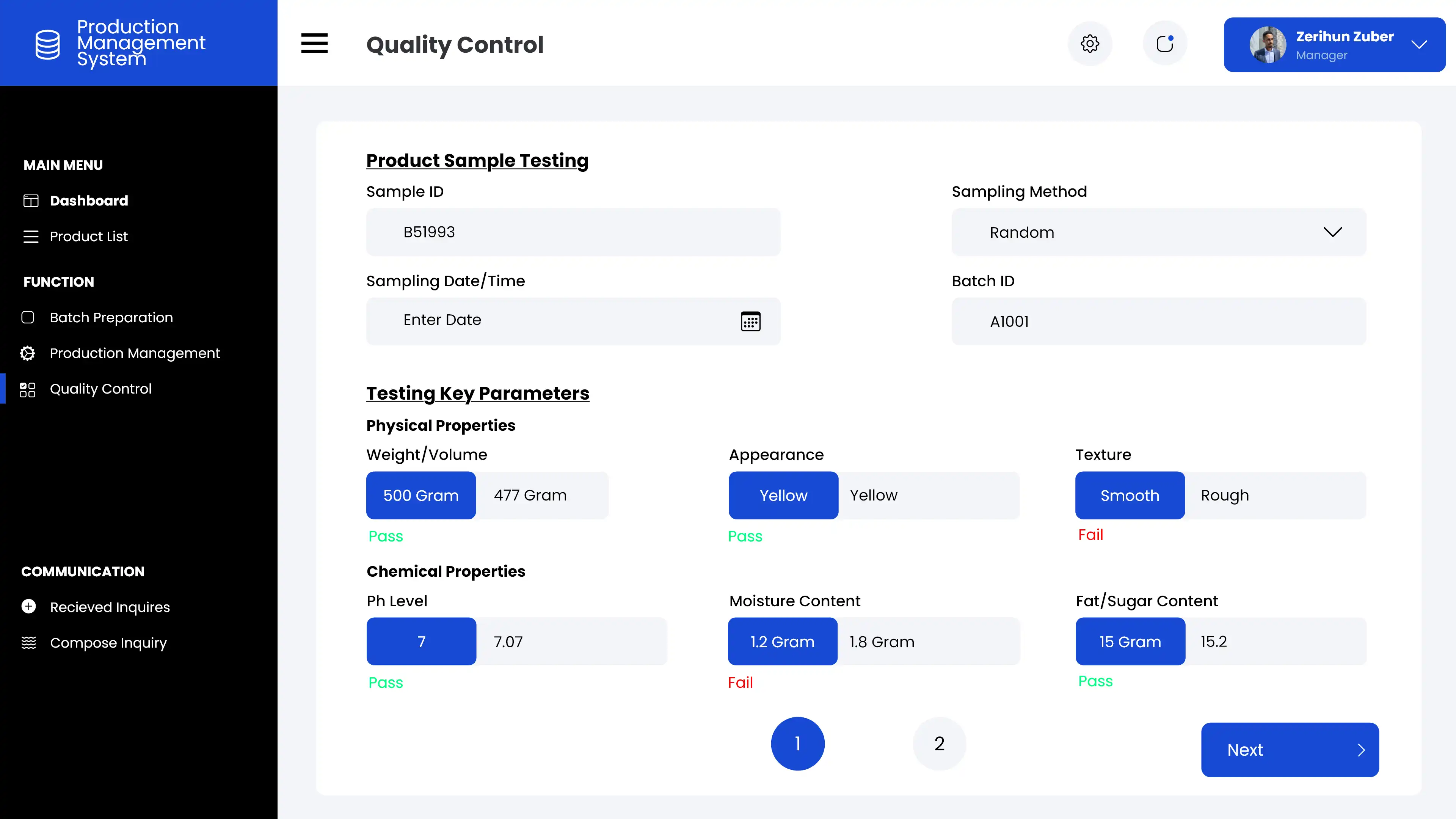

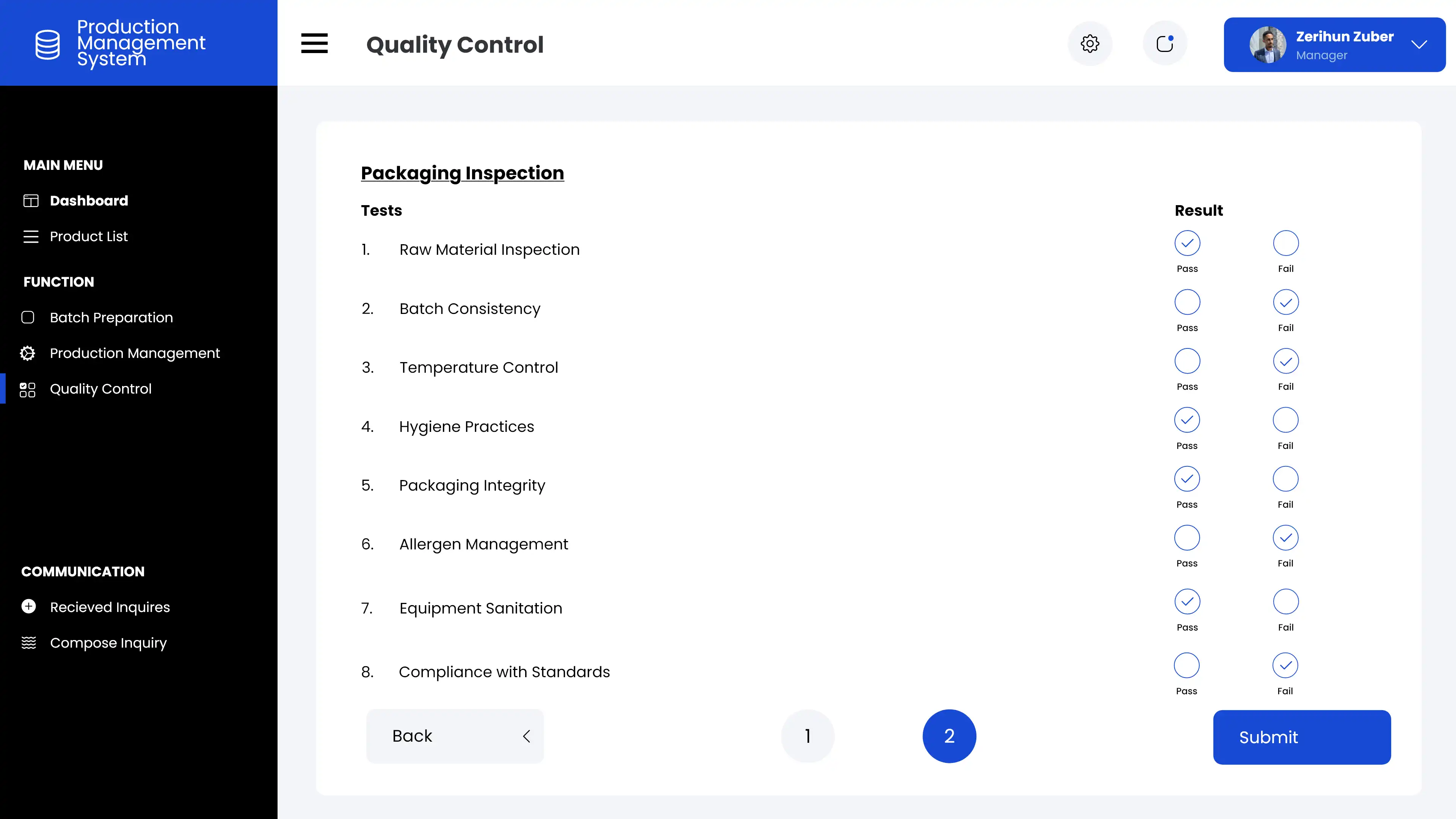

Ensure product quality through rigorous inspection and real-time comparisons against predefined manufacturing standards.

Comprehensive testing to ensure product strength, safety, and packaging reliability, giving you full confidence before market release.

Our production management system is purpose-built to fit the specific needs of your business, optimize manufacturing processes, and scale with your growth. It offers a tailored solution that enhances efficiency, ensures seamless coordination, and adapts as your production demands evolve.

Designed to meet the unique requirements of various industries, providing a customized approach to managing production workflows.

Streamlines production processes, reduces manual intervention, and enhances efficiency for improved output and quality control.

Adapts as your business expands, offering flexibility to manage production across multiple facilities and increasing production capacity.

This system will help agro-processing companies by managing production schedules, tracking raw material inventory (such as grains, spices, or vegetables), and optimizing processing lines. It will reduce delays, improve efficiency, and ensure timely delivery of processed products to meet local and export demands.

In the growing food and beverage sector, this system will help manage production processes, track inventory of locally sourced ingredients (like grains or coffee), and ensure compliance with health and safety regulations. It will improve planning and reduce waste by optimizing resource allocation and ensuring quality control.

For textile manufacturers, this system will help manage fabric inventory, track production stages, and monitor labor costs in garment production. It will enhance forecasting, efficient material usage, and ensure on-time delivery to meet both local demand and export requirements.

In the construction sector, this system will assist in managing the production of building materials like cement, steel, and roofing materials. It will optimize inventory, track production schedules, and ensure that materials are available for large-scale infrastructure projects and housing developments.

This system will assist in managing the production of consumer goods, electronics, and automotive parts by ensuring seamless workflow coordination. It will optimize inventory by tracking raw materials and minimizing waste. The system will track production schedules to prevent bottlenecks and improve efficiency. Additionally, it ensures real-time monitoring for quality control, reducing defects and maintaining compliance with industry standards.

Optimize Production – Drive Efficiency with Our Manufacturing System!